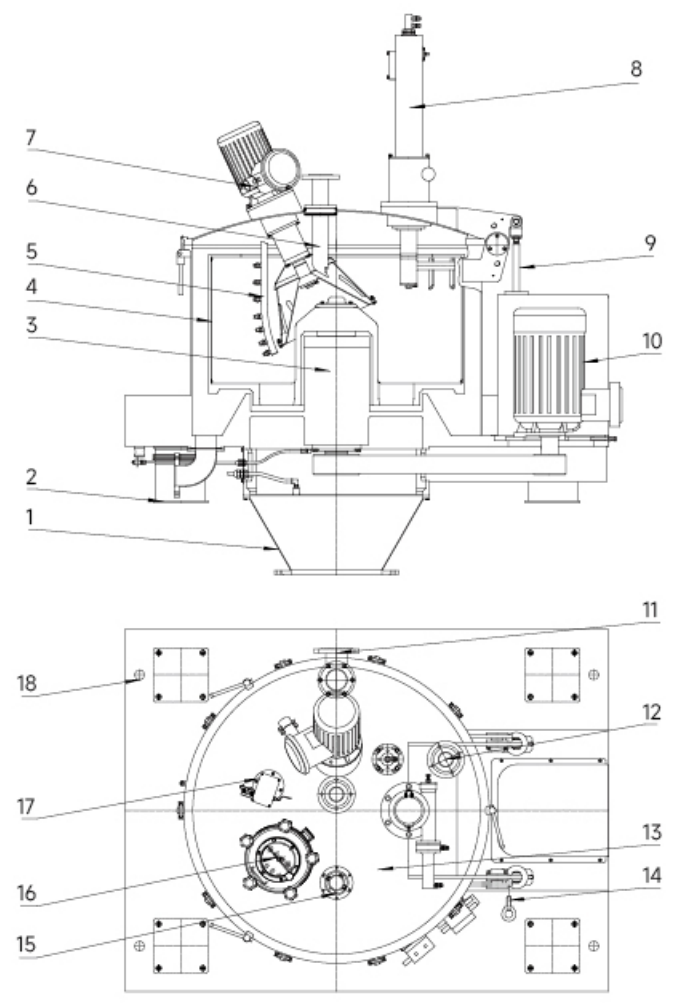

Автоматическая центрифуга с донным скребком представляет собой вертикальную центрифугу с автоматической фильтрацией. Двигатель приводит корзину во вращение с высокой скоростью через ленту, и под управлением предварительно написанной программы материал, подлежащий разделению, подается в корзину через систему подачи.

После фильтрации материала через фильтрующий материал (фильтрующую ткань/сетку) под действием центробежной силы жидкая фаза выводится из центрифуги через жидкостный трубопровод, а твердая фаза остается в корзине. Устройство контроля за материалом используется для определения положения заполнения корзины в режиме реального времени, и когда количество твердого осадка, осажденного в корзине, достигает заданной вместимости центрифуги, подача прекращается. Затем твердый осадок промывается и высушивается.

После того, как твердый осадок соответствует требованиям для удаления, центрифуга снижает скорость вращения до режима соскабливания, под гидравлическим (пневматическим) управлением скребковое устройство удаляет твердый осадок, после чего осадок выгружается через нижний выходной патрубок центрифуги.

Название компании :

JiangsuTusheng Centrifuge Manufacturing CO.,LTD.Brand :

Tusheng Категории продуктов

Категории продуктовThe company has been committed to the R&D, production and sales of centrifuges, boasting rich experience in the design and manufacturing of separation equipment. Its products have obtained ISO 9001:2015 Quality Management System Certification, ISO 14001:2015 Environmental Management System Certification, and ISO 45001 Occupational Health and Safety Management System Certification. The various centrifuges produced are widely used in chemical industry, pharmaceutical industry, food industry, environmental protection, new energy, salt production and other fields. In 2018, the company introduced high-end technical talents and R&D teams in filtration and separation, invested heavily in purchasing automatic welding robots, CNC machining centers, 500-ton hydraulic presses and other equipment, and achieved mold-based production.

With an annual sales volume of 235 million RMB, the company has 185 employees, covering an area of nearly 20,000 square meters, including a workshop area of over 15,000 square meters. It owns more than 100 sets of various processing and testing equipment, such as large vertical lathes, hydraulic presses, turning-milling-planing machines, boring machines, plate shears, bending machines, X-ray flaw detectors, display-type universal material testing machines, universal plate bending machines, CNC laser cutting machines, microcomputer vibration aging devices, and dynamic balancing machines. The company offers a complete range of centrifuges, mainly including top discharge models (PSB, PSD), automatic bottom discharge scraper models (PGZ, LGZ, PAUT, PGD), and horizontal spiral discharge models (LW, LLW, LLWZ), etc.

·Flat vertical scraper automatic discharge centrifuge

·Flat-plate scraper bag shaking automatic discharge centrifuge

·Flat plate discharge centrifuge

·Horizontal screw concentration and filtration centrifuge

·Horizontal screw discharge sedimentation centrifuge

Основные характеристики LGZ/PGZ

В процессах разделения твердой и жидкой фаз,неполное удаление тортаЭто может значительно снизить эффективность и увеличить время простоя. В этой статье объясняется, почему.автоматические вертикальные центрифуги со скребкомЭто эффективное решение, помогающее пользователям понять, как усовершенствованные конструкции скребкового и нижнего разгрузочного оборудования решают распространенные проблемы разгрузки в промышленных центрифугах.

Дополнительные конфигурации LGZ/PGZ

Центрифуги серии LGZ/PGZ представляют собой тип центробежного сепарационного оборудования с высоким научным уровнем, доступного в различных конфигурациях. Благодаря асептическим, санитарно-гигиеническим, взрывозащищенным системам защиты и множеству вариантов комплектации, центрифуги этой серии управляются полностью автоматической программой и широко используются в фармацевтической, химической, энергетической, пищевой и других отраслях промышленности.

| предметы | LGZ/PGZ800 | LGZ/PGZ1000 | LGZ/PGZ1250 | LGZ/PGZ1500 | LGZ/PGZ1600 | LGZ/PGZ1800 |

|---|---|---|---|---|---|---|

| Диаметр корзины (мм) | 800 | 1000 | 1250 | 1500 | 1600 | 1800 |

| Объем корзины (л) | 100 | 190 | 400/500 | 610 | 800/1000 | 1000 |

| 限量 Макс. нагрузка (кг) | 135 | 255 | 500/600 | 820 | 1000/1200 | 1250 |

| Максимальная относительная скорость (об/мин) | 1200/1500 | 1100/1200 | 1100/1200 | 850 | 850 | 800 |

| Центрифужная сила | 645/1008 | 677/805 | 700/1008 | 606 | 647 | 645 |

| Двигатель (кВт) | 7,5/11 | 15 | 22/30 | 37 | 37/45 | 55 |

| Размеры (Д)WХм) | 1850*1250*2050 |

2200*1500*2250 | 2550*1800*2550 |

2900*2100*2700 | 3200*2400*3000 |

3500*2500*3400 |

| Вес (кг) | 2000 | 3500 | 6000 | 8000 | 12000 | 15000 |